Sasol alumina adds years to life - and life to years

15 Nov 2023

United States

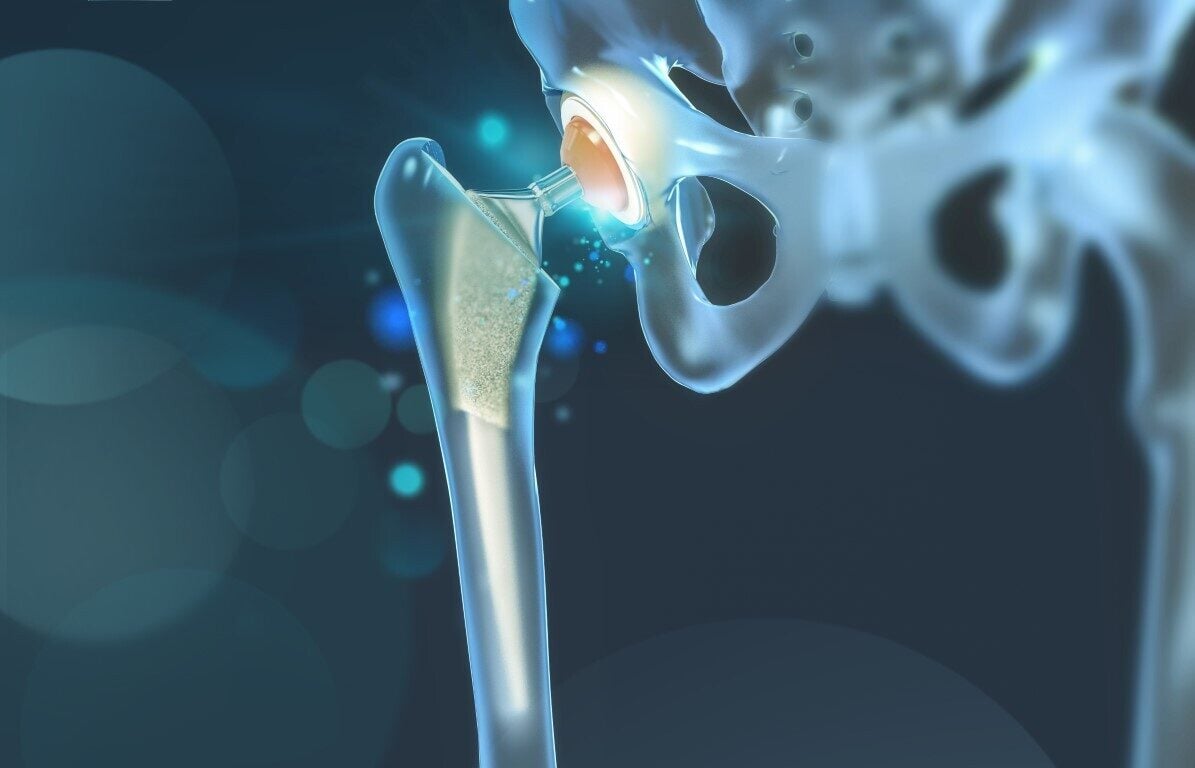

Until recently, hip problems caused by aging or injury meant a severely diminished lifestyle marked by pain and lack of mobility.

The earliest attempts at replacing elements of the human hip began in the late 19th century. Over the years, multiple materials were used, from ivory to metal and eventually, plastics. All had significant drawbacks.

Today, patients around the world benefit from the unique chemistry developed by Sasol Chemicals' Advanced Materials business, which is adding years to life - and life to years - by providing the high-purity medical grade alumina used in modern ceramic artificial hip joints.

Ceramic joints have significant advantages over conventional hip replacement systems, which use an insert made of plastic and a head made of metal.

Patients with ceramic-based hip joints have up to five times fewer medical complications compared to those with joints made from non-ceramic materials. That's because ceramic components have a high level of biocompatibility and don't leach metals into the body. Plus, the sintered alumina-based material used in medical grade ceramics is one of the hardest substances in the world, second only to diamonds. So ceramic hip joints can withstand years of wear and tear, giving them a longer lifespan than conventional metal-on-plastic joints, which often needed replacing after 10-15 years.

The alumina used in today's artificial hip joints is a dense, ceramic composite, obtained from aluminum oxide powder which is further processed and sintered into a precision shape. Its use in hip replacement technologies is just one of the ways that Sasol Chemicals innovates for a better world.