DISPAL / DISPERAL

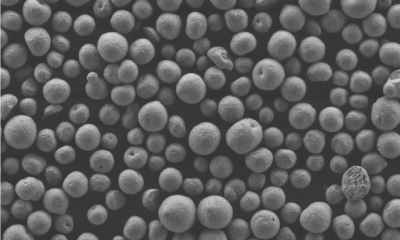

DISPERAL and DISPAL are the trademarks for the high-purity, highly dispersible boehmite powders and sols/dispersions manufactured by Sasol in Brunsbüttel, Germany, and in Lake Charles, Louisiana, USA. In the dispersed phase these boehmites, exhibit a unique combination of purity, consistency and dispersibility that make them excellent materials for use in colloidal applications. The Sasol range of dispersible boehmites has traditionally been used in applications such as sol-gel ceramics, catalysis, refractory materials, rheology control and surface frictionising.

Other applications include surface coating as well as paint detackification, polymer-additives and functional fillers

Reach out to Sasol Chemicals' technical experts to learn more about the full range of products and discuss how Sasol can provide material to fit individual requirements.

Other applications include surface coating as well as paint detackification, polymer-additives and functional fillers

Reach out to Sasol Chemicals' technical experts to learn more about the full range of products and discuss how Sasol can provide material to fit individual requirements.

Chemical Family

Boehmite

CAS No.

1318-23-6

Synonyms

alumina hydrate, aluminium oxyhydroxide, aluminium oxide hydroxide, hydrous aluminium oxide,aluminium hydroxide oxide

Features

High purity, dispersible boehmite

Regional Availability

Global

Regulatory & Compliance

Contact our sales team for region specific compliance & regulatory information

Dispersibility Characteristics | Featured Products | Crystallite size [nm] | Maximum weight loading [%] | Dispersed Particle size range (d50) [nm] |

|---|---|---|---|---|

Water Dispersible Boehmites | DISPAL 23N4-80, DISPAL 11N7-80, DISPERAL P2, | 4.5 - 100 | 10 - 40, depending on specific product | 20-350 |

Alkaline Dispersible Boehmites | DISPAL 23C9-80, DISPAL 18C9-80, DISPERAL HP14/7 | 7.5 - 15 | 10 - 15 | 100-320 |

Acid Dispersible Boehmites | DISPAL 28, DISPERAL, DISPERAL 40, DISPERAL 60 | 4.5 - 350 | 25 to > 40, depending on specific product | 20-350 |

Solvent Dispersible Boehmites | DISPAL 10C, DISPAL 10D21, DISPAL 10SR | 40 - 50 | depending on solvent | 30 - 350 |

Dispersible Boehmite High Porosity | DISPAL 18HP, DISPERAL HP 14, DISPERAL HP 18 | 14-18 | 35 | 100 - 200 |

Dispersibility Characteristics

Water Dispersible Boehmites

Featured Products

DISPAL 23N4-80, DISPAL 11N7-80, DISPERAL P2,

Crystallite size [nm]

4.5 - 100

Maximum weight loading [%]

10 - 40, depending on specific product

Dispersed Particle size range (d50) [nm]

20-350

Dispersibility Characteristics

Alkaline Dispersible Boehmites

Featured Products

DISPAL 23C9-80, DISPAL 18C9-80, DISPERAL HP14/7

Crystallite size [nm]

7.5 - 15

Maximum weight loading [%]

10 - 15

Dispersed Particle size range (d50) [nm]

100-320

Dispersibility Characteristics

Acid Dispersible Boehmites

Featured Products

DISPAL 28, DISPERAL, DISPERAL 40, DISPERAL 60

Crystallite size [nm]

4.5 - 350

Maximum weight loading [%]

25 to > 40, depending on specific product

Dispersed Particle size range (d50) [nm]

20-350

Dispersibility Characteristics

Solvent Dispersible Boehmites

Featured Products

DISPAL 10C, DISPAL 10D21, DISPAL 10SR

Crystallite size [nm]

40 - 50

Maximum weight loading [%]

depending on solvent

Dispersed Particle size range (d50) [nm]

30 - 350

Chemical Family

Boehmite

CAS No.

1318-23-6

Synonyms

alumina hydrate, aluminium oxyhydroxide, aluminium oxide hydroxide, hydrous aluminium oxide,aluminium hydroxide oxide

Features

High purity, dispersible boehmite

Regional Availability

Global

Regulatory & Compliance

Contact our sales team for region specific compliance & regulatory information